Logo of the recycling fabric-brand Ecopak at extremtextil

ECOPAK™ from Challenge Sailcloth

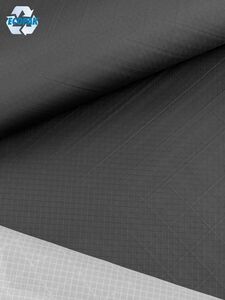

Challenge Sailcloth is a world-renowned manufacturer of sailcloth, canvas, and many other fabrics for the marine industry with decades of experience. With its sustainable ECOPAK™ backpack laminates, Challenge Sailcloth has been offering a backpack laminate made from 100% recycled polyester since 2020. The new ULTRA range is also designed for maximum performance, which is achieved through a new construction and a very high proportion of ultra-high-strength UHMWPE fibers. Similar to a sail laminate, both ECOPAK™ and ULTRA feature an outer fabric laminated with a UV-stable, highly waterproof polyester film or ripstop polyester. The area of application is determined by the use of different outer fabrics.

In ECOPAK™, the blue CrossPly polyester fibers typical of sail laminates are located between the outer fabric and the polyester film or lining. These increase tear resistance and prevent the material from stretching in all directions. The CrossPly fibers, arranged diagonally in a diamond pattern, give the ECOPAK™ backpack laminates their typical technical look. In the EPLX versions, the smooth film is on the inside, while in the EPX styles, a thin, slightly transparent 70 denier ripstop polyester lining is laminated on the inside. This thin lining gives the fabric additional stability, e.g. at particularly stressed seams, and ensures brightness inside backpacks and bags. The area of application is determined by the strength of the outer fabric and the associated abrasion and tear resistance. Fabrics from 70 denier to 1680 denier are used as outer fabrics.

ECOPAK™ from Challenge Sailcloth

With ECOPAK™, Challenge Sailcloth focuses not only on performance but also on sustainability:

- All components of ECOPAK™ laminates are made from 100% recycled polyester. This means that over 20 plastic bottles are recycled per meter and more than 450g of carbon dioxide is saved.

- The outer fabric is made from REPREVE® yarns collected from the ocean, and all other components are made from post-consumer PET bottles

- Only environmentally friendly, PFC-free C0 impregnations are used

- All adhesives are solvent-free

- No volatile organic compounds (VOCs) are used in the production of ECOPAK™

- Thanks to an innovative production process, energy-intensive drying processes during lamination are reduced

- ECOPAK™ lies flat on the table when cut and has evenly distributed CrossPly fibers from edge to edge, which prevents waste during cutting.

- The polyester outer fabric used is as abrasion-resistant as or even more abrasion-resistant than similar nylon fabrics and is therefore very durable.

- Since ECOPAK™ is made from 100% polyester, it is completely recyclable

Our ECOPAK® styles at a glance

Overview of Ecopak®-Styles:

| ECOPAK style | Outer fabric | Reinforcement fibers | Backing | Weight (manufacturer's specifications) |

|---|---|---|---|---|

| EPX200 | 200 denier polyester | 45° Blue CrossPly | 70 denier ripstop lining | 200.1 g/m² |

| EPX400 | 400 denier polyester | 45° Blue CrossPly | 70 denier ripstop lining | 281 g/sqm |

| EPX600 | 600 denier polyester | 45° Blue CrossPly | 70 denier ripstop lining | 345 g/m² |

| EPLX200 | 200 denier polyester | 45° Blue CrossPly | 0.5 mil RUV™ matter film | 145.8 g/sqm |

| EPLX400 | 400 denier polyester | 45° Blue CrossPly | 0.5 mil RUV™ matter film | 215.3 g/m² |

| EPLX600 | 600 denier polyester | 45° Blue CrossPly | 0.5 mil RUV™ matte film | 300.1 g/m² |

| EPLX840 | 840 denier ballistic polyester | 45° Blue CrossPly | 0.5 mil RUV™ matte film | 332.2 g/m² |

| EPLX1680 | 1680 denier ballistic polyester | 45° Blue CrossPly | 0.5 mil RUV™ matte film | 416.9 g/sqm |