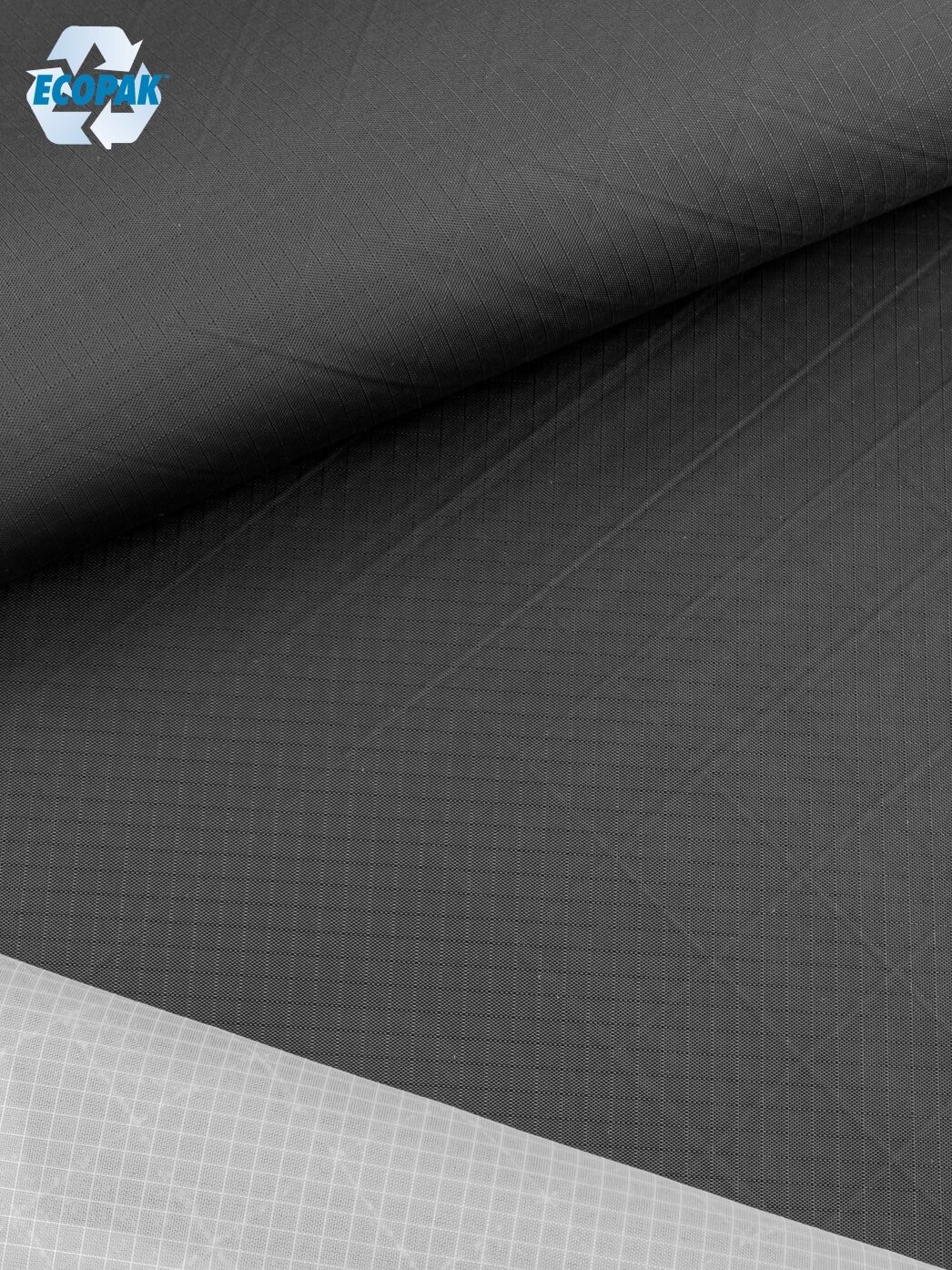

ECOPAK® EPX70 RS, Ripstop,, recycling-backpack-laminate, 171g/sqm

€31.90/meter

incl. 19 % VAT plus

Please select your variant:

When folded for shipping the laminate will get permanent folding marks. This does not affect the technical properties. If you wish to receive the material without folding marks, please choose "shipping on the roll" during checkout.

Meter

Product information

ECOPAK® EPX70 RS, Ripstop,, recycling-backpack-laminate, 171g/sqm

Lightweight version of the ECOPAK™ backpack laminate with lining laminated on the inside. To optimize weight, a ripstop polyester is used on the outside.

ECOPAK™ by Challenge Sailcloth is a sustainable backpack laminate made from 100% recycled polyester. Similar to sailcloth laminates, this fabric laminates an outer fabric together with a UV-stable, waterproof polyester film or ripstop polyester. The strong, blue CrossPly polyester fibers, which lie in a diamond shape between the layers, increase tear strength and prevent the material from stretching in all directions, thus increasing dimensional stability. In addition, the CrossPly fibers give ECOPAK™ its typical, technical look. In the EPLX styles, the smooth film is on the inside, while in the EPX styles a lining of 70den ripstop polyester has been laminated on. This lining additionally reinforces the fabric. At particularly stressed seams, it stabilizes the material. It also provides a light interior in backpacks and bags. The area of application is determined by the strength of the outer fabric and the associated abrasion and tear resistance.

In developing ECOPAK™, Challenge Sailcloth focused on sustainability in addition to performance:

- All components of the ECOPAK™ laminates are made from 100% recycled polyester. This means that meter for meter, over 20 plastic bottles are recycled and more than 450g of carbon dioxide is saved.

- The outer fabric is made from REPREVE® yarns collected in the ocean, and all other components are made from used PET bottles

- Only FC-free C0 impregnations are used.

- No VOCs (Volatile Organic Compounds) are used in the production of ECOPAK™, all adhesives are solvent-free

- Thanks to an innovative production process, energy-intensive drying processes during lamination are reduced

- ECOPAK™ lies very flat when cut and has a very uniform CrossPly fiber from edge to edge - this prevents waste during cutting

- The polyester outer fabric used is similarly abrasion resistant to fabric made from nylon, making it very durable

- Because ECOPAK™ is made from 100% polyester, it is recyclable

ECOPAK™ EPX70 RS combines a 70den lightweight ripstop recycled polyester with a 70den ripstop lining. In between, at a 45° angle, are the blue CrossPly fibers. EPX70 RS is a great choice for small, lightweight backpacks, accessories or lining. For bottom panels and high abrasion areas we recommend ECOPAK™ versions with a stronger outer fabric.

Short info

Technical Informations

Further links to " ECOPAK® EPX70 RS, Ripstop,, recycling-backpack-laminate, 171g/sqm"