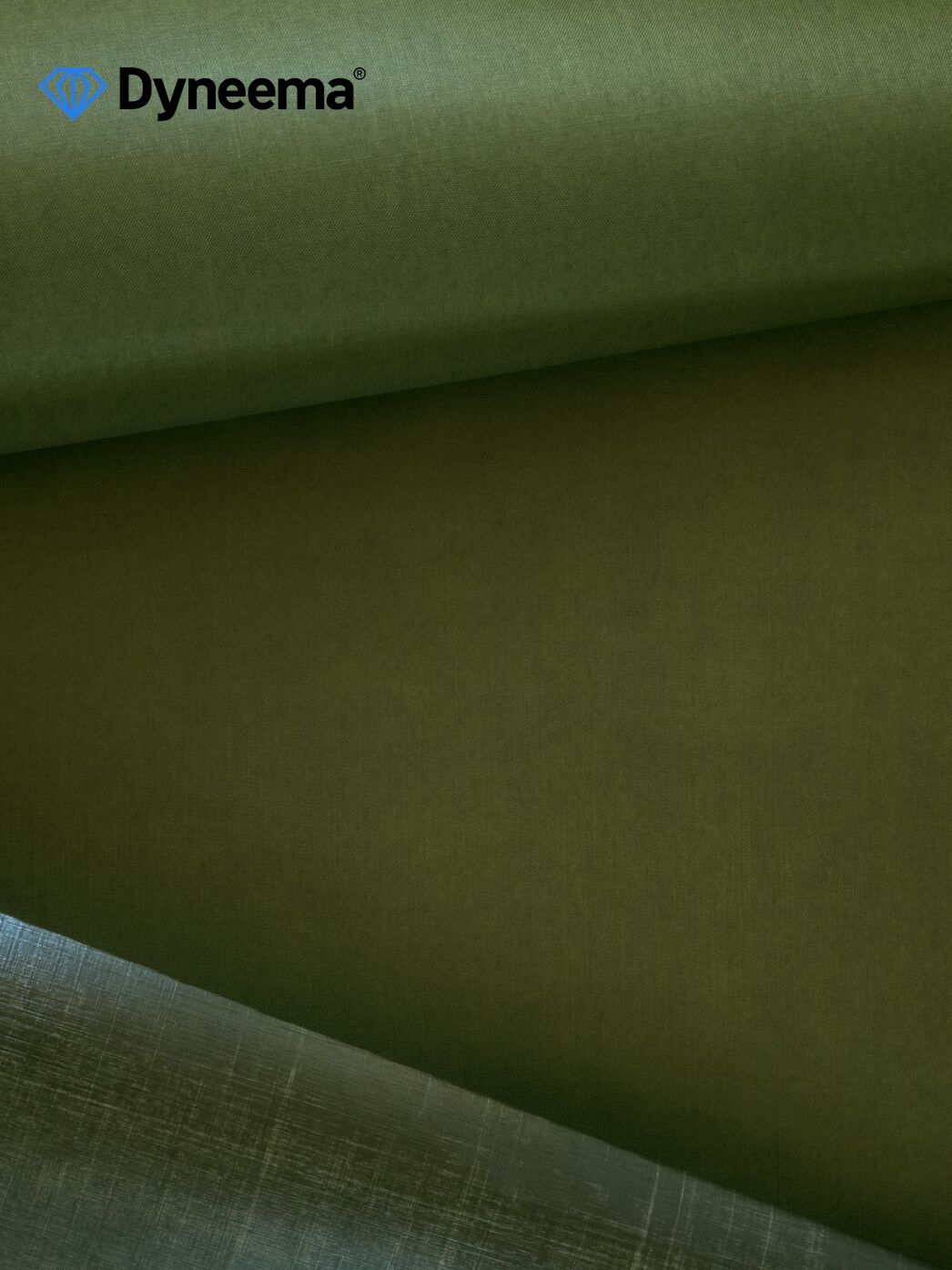

Dyneema® composite fabric + woven, CT5K.18/wov32c, 102g/sqm

€53.90/meter

incl. 19 % VAT plus

Please select your variant:

When folding the laminate into a carton it will get permanent folding marks that don't affect the technical properties. If you wish to receive the material without folding marks, please choose "shipping on the roll" during checkout. DCF is still folded all 9m during production so those marks can't be avoided.

Meter

Product information

Dyneema® composite fabric + woven, CT5K.18/wov32c, 102g/sqm

Cuben fiber has a new name: "Dyneema® Composite Fabric"! The material is the same as before, but besides the new name we can now offer it as a distributor for DSM in in far more styles and colours and at much better conditions!

Dyneema® Composite Fabrics is a performance laminate, that was originally invented for high-end cruising sails. The concept is well known in the sailing-industry: Strong fibers are being laminated between two carriers. What makes DCF special are the ultra-strong Dyneema®-fibres that are used. Dyneema® combines extremely high tear-strength with ultralight weight. Not without reason it is called "The world's strongest fiber"! Due to the unique properties of the fibers DCF is highly waterproof, doesn't stretch, is resistant to folding, doesn't soak water, is UV- and chemical-resistant. The application range is determined by the amount of Dyneema®-fibers and various carrier materials that are used. The standard Dyneema® Composite Fabrics have a smooth Polyester-film on each side that makes it highly waterproof and can be easily glued. So-called HYBRIDs widen the application range by using different additional layers like woven fabrics, membranes or glues to optimize it for special applications like backpacks or breathable garments.

The style CT5K.18wov32c is a so-called HYBRID DCF fabric since it is equipped with an additional 50 denier polyester fabric on the outside. This significantly enhances the abrasion-resistance and gives the laminate a more textile appearance. On the inside it has the typical thin, transparent polyester film that makes it waterproof and can be easily glued. The super-strong Dyneema®-fibers between the two layers give it an extremely high tear-resistance for its weight. This style has a reduced amount of Dyneema®-threads, so with 102g/sqm it is the lightest HYBRID-version available and ideal for ultralight but still durable backpacks, bags, pouches and accessories.

Bio Based Dyneema® is used for this article. In Bio Based Dyneema®, residues from the wood and pulp industry are mixed with fossil raw materials during the manufacturing process. Due to the proportion of renewable raw materials, the ethylene produced has a significantly better CO2 balance than conventional HMPE. The technical properties of Bio Based Dyneema® are identical to conventional Dyneema®. Bio Base Dyneema® is ISCC-certified.

Short info

Technical Informations

Further links to " Dyneema® composite fabric + woven, CT5K.18/wov32c, 102g/sqm"

Article No.: 71157

€52.90/pieces

Article No.: 70589

€34.90/pieces

Article No.: 71157

€52.90/pieces

Article No.: 70589

€34.90/pieces