Logo of the fabric-brand Challenge Ultra at extremtextil

ULTRA™ by Challenge Sailcloth

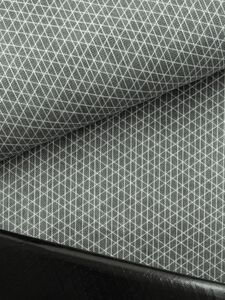

Challenge Sailcloth's ULTRA laminates use a blend of ultra-high-strength UHMWPE fibers and polyester for the outer fabric. Thanks to the very high proportion of 67% UHMWPE fibers, maximum abrasion resistance, tear strength, and durability are achieved. This blend is combined with a matt, waterproof and UV-stable 0.5 mm polyester film made from recycled polyester on the inside. The result is the ultimate ultra-lightweight backpack fabric! Areas subject to high point loads, such as shoulder strap attachments or daisy chains, should be reinforced with an additional layer of fabric to prevent tearing.

Challenge Sailcloth also had sustainability in mind when developing the ULTRA laminates. However, the focus is on performance, which leads to slight compromises in terms of sustainability:

- The UHMWPE fibers are made from fossil-based materials. Sustainable alternatives are not technically feasible at this time.

- Recycled polyester is used for the polyester content in the outer fabric, depending on market availability. If you want your backpack fabric to be 100% recycled, we recommend ECOPAK® laminates, which are made from 100% recycled polyester

- The UV-stable PU film used consists of recycled polyester from post-consumer PET bottles.

- Only environmentally friendly PFC-free C0 impregnations are used.

- No VOCs (volatile organic compounds) are used in the production of ULTRA.

- All adhesives are solvent-free

- Thanks to an innovative production process, energy-intensive drying processes during lamination are reduced

| ULTRA® style | Outer fabric | Backing | Weight (manufacturer's specifications) | CrossPly |

|---|---|---|---|---|

| ULTRA® 100 X | 100 den Ultra-PE (UHMWPE) / high-strength polyester | 0.75 mil UV-stable PET film made from recycled polyester | 112 g/sqm | Ultra™ CrossPly |

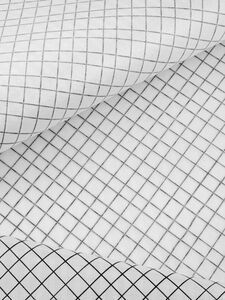

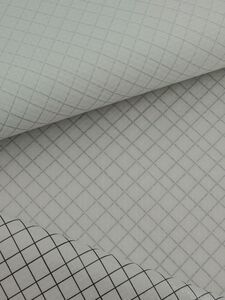

| ULTRA® 100 X PSA self-adhesive | 100 den Ultra-PE (UHMWPE) / high-strength polyester | * 0.75 mil UV-stable PET film made from recycled polyester, pressure-sensitive adhesive, protective paper with metric grid | 112 g/m² + adhesive | Ultra™ CrossPly |

| ULTRA® 200 X | 200 den Ultra-PE (UHMWPE) / high-strength polyester | 0.75 mil UV-stable PET film made from recycled polyester | 133 g/sqm | Ultra™ CrossPly |

| ULTRA® 400 X | 400 den Ultra-PE (UHMWPE) / high-strength polyester | 0.75 mil UV-stable PET film made from recycled polyester | 178 g/sqm | Ultra™ CrossPly |

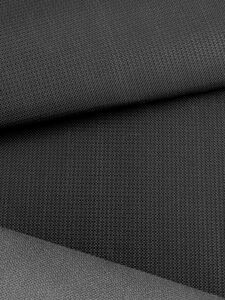

| ULTRA® TX50 | 50d triple ripstop high tenacity polyester | 0.25 mil UV-stable PET film | 82 g/sqm | Ultra™ CrossPly |

| ULTRA® TX70 | 70d recycled polyester ripstop | 0.25 mil UV-stable PET film | 99 g/m² | Ultra™ CrossPly |

| ULTRA® 100 (no longer manufactured) | 100 den Ultra-PE (UHMWPE) / high-strength polyester | 0.5 mil RUV™ matte film | 99 g/m² | None |

| ULTRA® 200 (no longer manufactured) | 200 den Ultra-PE (UHMWPE) / high-strength polyester | 0.5 mil RUV™ matt film | 119 g/m² | None |

| ULTRA® 400 (no longer manufactured) | 400 den Ultra-PE (UHMWPE) / high-strength polyester | 0.5 mil RUV™ matte film | 158 g/sqm | None |

| ULTRA® 800 (no longer manufactured) | 800 den Ultra-PE (UHMWPE) / high-strength polyester | 0.5 mil RUV™ matte film | 288 g/m² | None |

| ULTRA® 100 PSA self-adhesive (no longer manufactured) | 100 den Ultra-PE (UHMWPE) / high-strength polyester | * 0.5 mil RUV™ matte film, pressure-sensitive adhesive, protective paper with metric grid | 99 g/m² + adhesive | None |