ULTRA 200 X, backpack-laminate with UHMWPE, 133g/sqm

€67.90/meter

incl. 19 % VAT plus

Please select your variant:

Roll width 1470mm

When folded for shipping the laminate will get permanent folding marks. This does not affect the technical properties. If you wish to receive the material without folding marks, please choose "shipping on the roll" during checkout.

Meter

Product information

ULTRA 200 X, backpack-laminate with UHMWPE, 133g/sqm

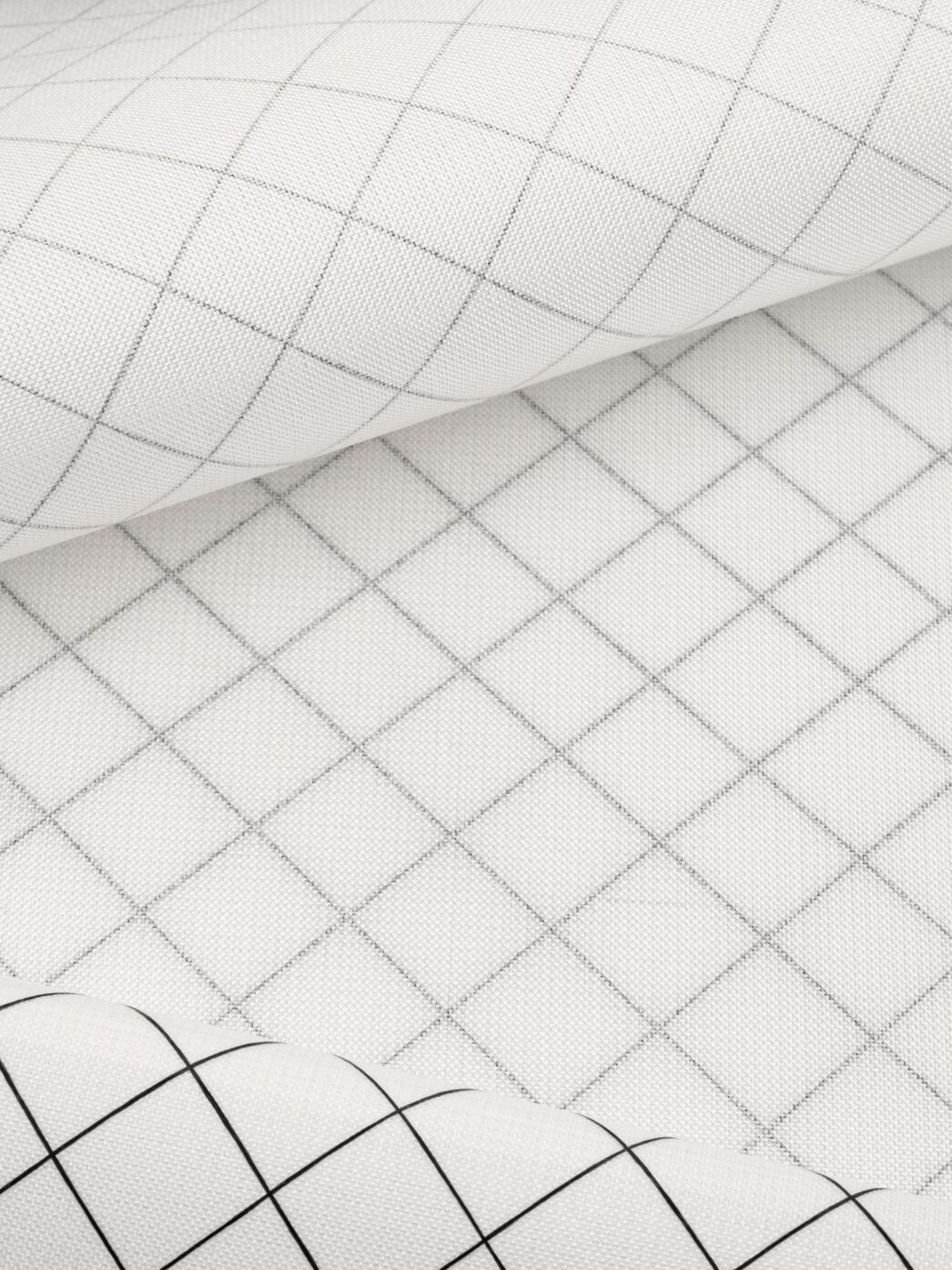

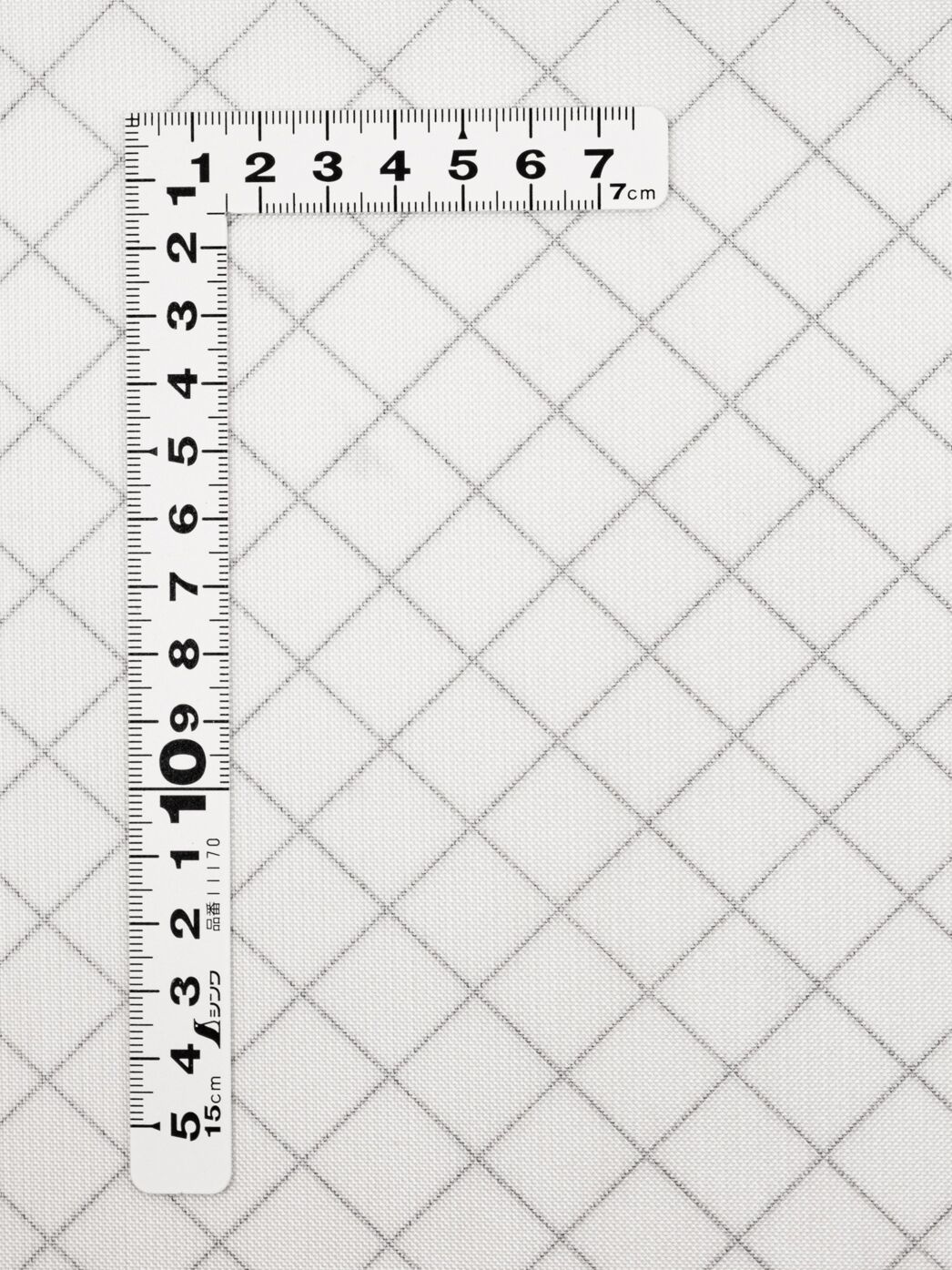

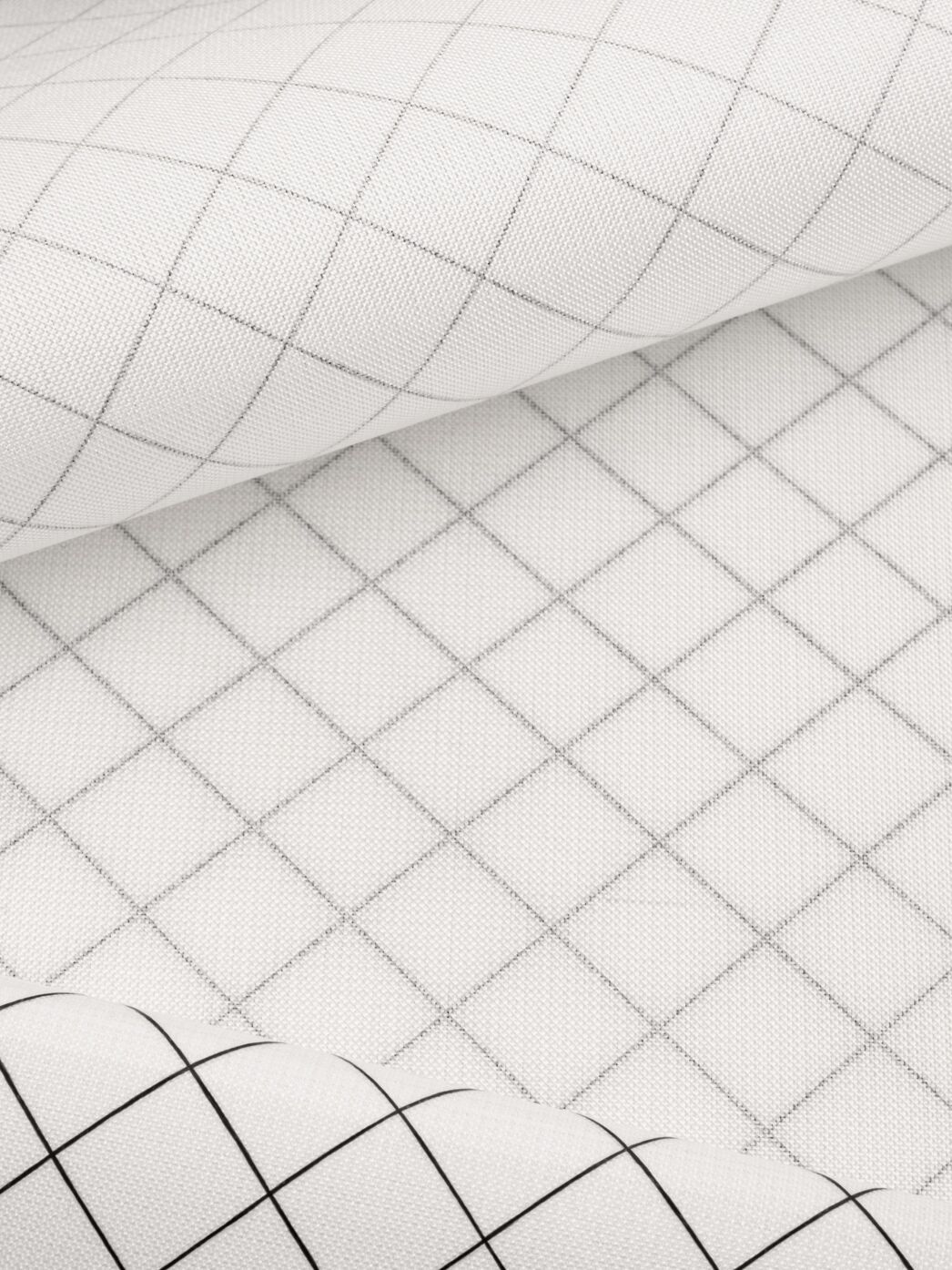

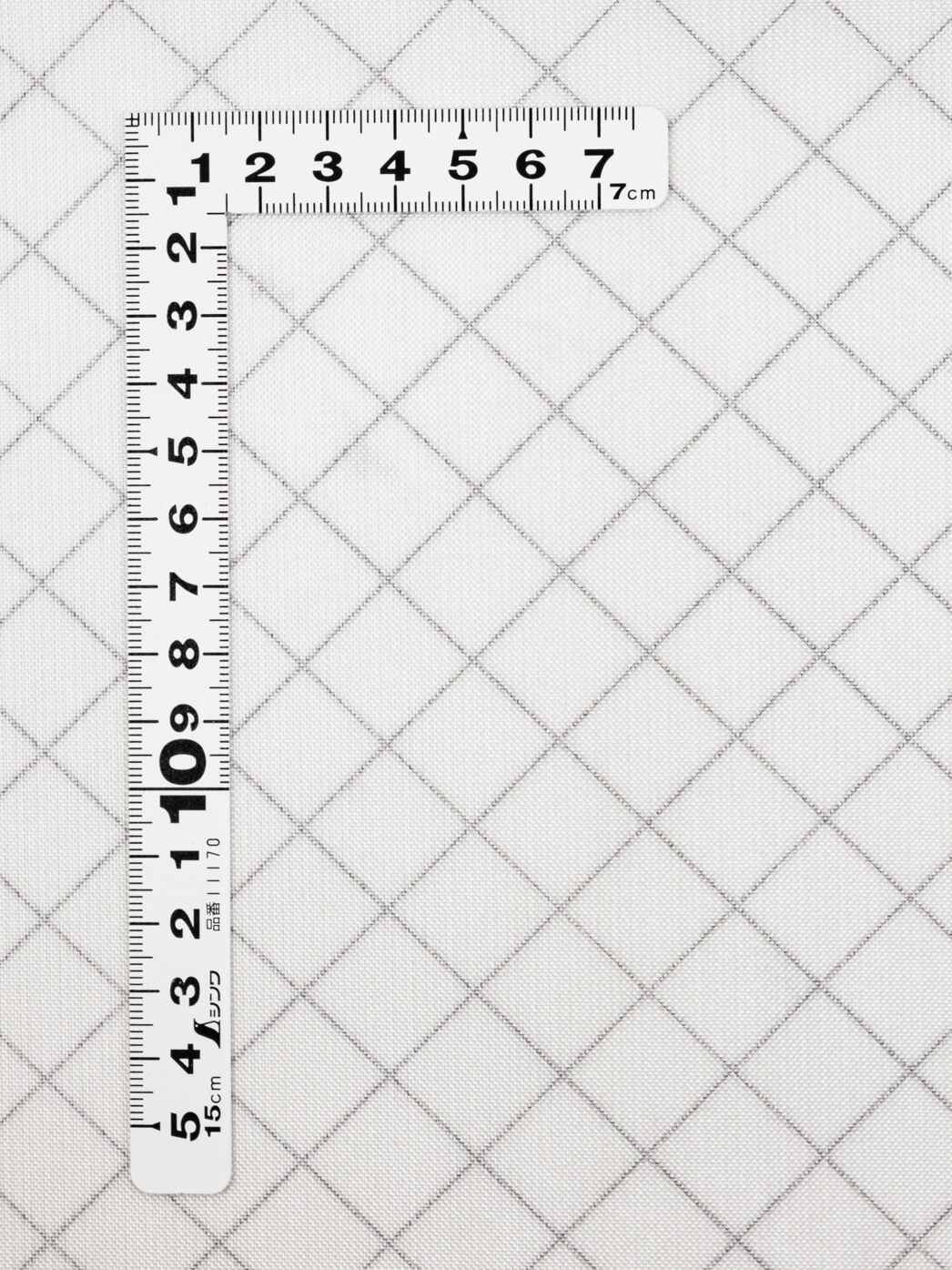

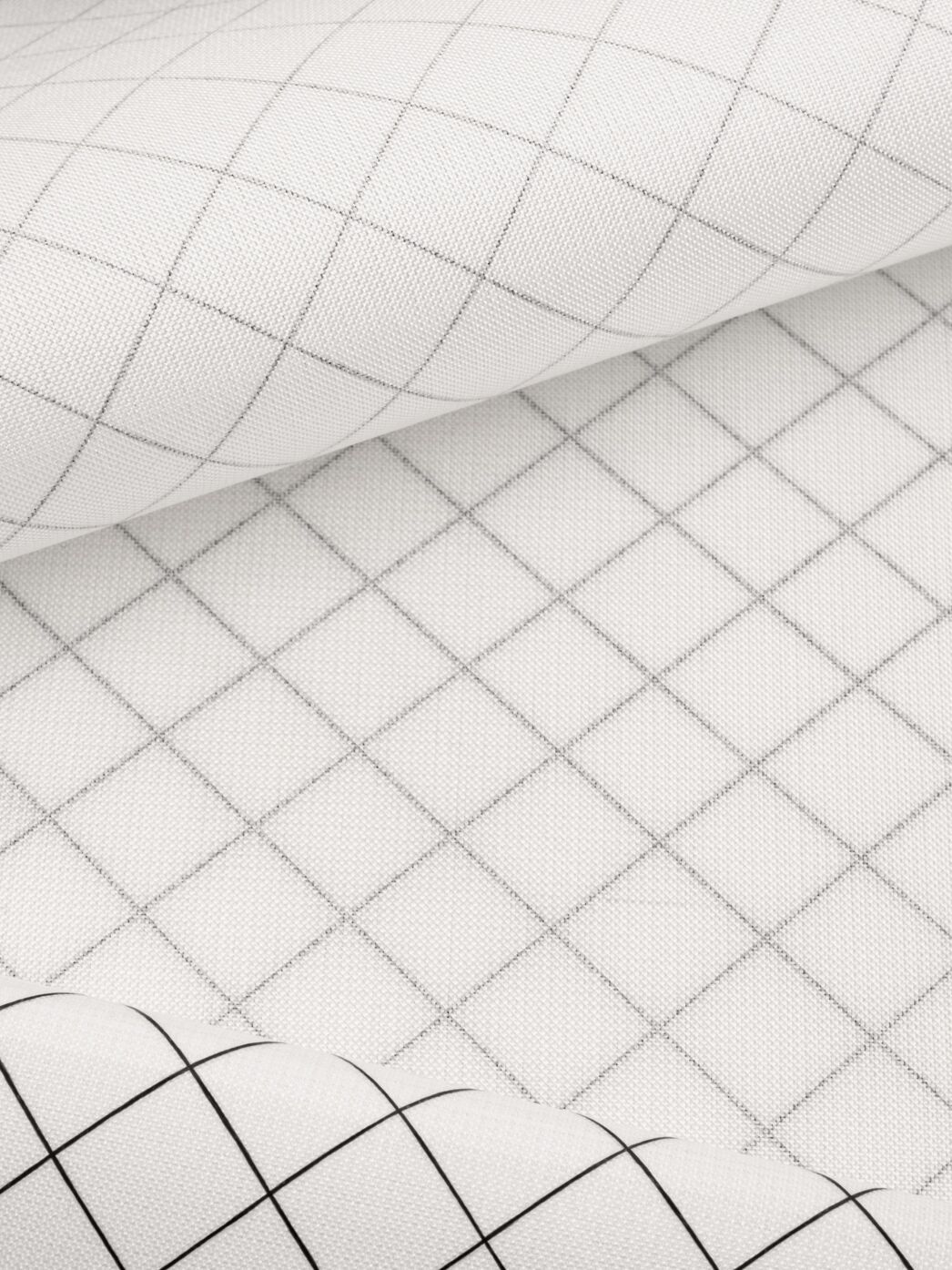

Challenge Sailcloth upgraded its ULTRA backpack laminates with additional crossply and a slightly stronger backing film. This new X-variant is thus more dimensionally stable and more reliably waterproof due to the thicker film. The ULTRA X laminates have a 3-layer structure: On the outside is a fabric made of high-strength UHMWPE fibers and high-tenacity polyester. UHMWPE fibers are currently considered the non-plus-ultra in terms of tear strength and abrasion resistance and are also known as Dyneema®, Spectra® or Tsuunoga®. The strong, black Ultra fibers, which lie in a diamond shape between the plies, increase the tear resistance and prevent the material from stretching in all directions. A matte, 0.75mil thick, waterproof polyester film is laminated to the inside. Due to the high percentage of 67% UHMWPE fibers, even the lightweight ULTRA variants achieve technical values in terms of abrasion resistance and tear strength that do not need to hide behind much stronger Cordura® fabrics. The polyester film ensures that ULTRA X is reliably waterproof and has very good dimensional stability. The range of use is determined by the strength of the outer fabric and the associated abrasion and tear resistance.

When developing the ULTRA laminates, Challenge Sailcloth focused on sustainability in addition to performance:

- The PES film used is made from 100% recycled polyester from post-consumer PET bottles

- Recycled polyester is used for the polyester content in the outer fabric, depending on market availability. If you value guaranteed 100% recycling, we recommend Challenge Sailcloth's ECOPAK® laminates.

- Only FC-free C0 impregnations are used

- No VOCs (Volatile Organic Compounds) are used in the production of ULTRA, all adhesives are solvent-free

- Thanks to an innovative production process, energy-intensive drying processes during lamination are reduced

ULTRA 200 X uses a blend of 200den UHMWPE fibers and high-tenacity polyester for the outer fabric. Thanks to the very high proportion of 67% UHMWPE fibers, this achieves maximum abrasion resistance, tear strength and durability for the weight of 133g/sqm. The Black Ultra fibers in the cross-ply increase dimensional stability and tear resistance. This blend is combined with a matte, waterproof and UV stable 0.75mil polyester film on the inside. The result is the ultimate ultra-lightweight backpacking fabric! Areas with heavy point loading such as shoulder strap attachments or daisy chains should be backed with an additional layer of fabric to prevent tearing due to the thinness of the material.

Short info

Technical Informations

Further links to " ULTRA 200 X, backpack-laminate with UHMWPE, 133g/sqm"